|

Design and Making of plastic injection molds |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

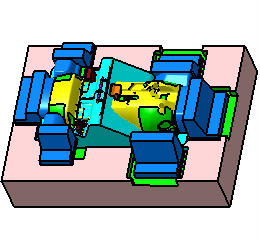

| Mold Designing |

|

| Early in the process, we repeatedly review the design with the customer and reflect the product and production requirements in the design. We also have an in-house review of the design drawing. The opinions expressed in the meeting and the proposals from each section are utilized by the whole company to reduce the number of man-hours and improve quality. We use CATIA, a mission-critical CAD program from the automobile industry, for the 3D modeling. |

|

|

| Modeling by CATIA/V5 |

Drawing by McHelix |

|

|

|

| Machining |

|

| We process the mold using a machining center, an electric discharge machine, and a wire-cutting electric discharge machine. We address the ever-increasing complexity of the mold structure and achieve processing accuracy as required by customers. During the day, processing that needs an accompanying operator is prioritized. At night, machining centers and electric discharge machines are operated unmanned with several kinds of tools and electrodes automatically replaced, while wire-cutting electric discharge machines conduct multiple processes based on programming. Thus, the rate of operation of the machines is increased to answer the need for short delivery time. |

|

|

| Milling Ribs by DNC |

Electric Discharging by Cu |

|

|

|

| Part processing, finishing, assembly, and mating |

|

| Parts incorporated into the mold are produced with a NC machine and a general-purpose machine.

|

|

|

| Milling Lift Core by DNC |

Polishing Ribs of Slide Core |

|

|

|

| In-house trial and evaluation of the mold |

|

| A new mold or a mold with a modified design is given a trial and checked using the companyÕs molding machine. The first trial is monitored by the designer, managers, and the person responsible for the mold. The mold is checked and its formability and molded items are evaluated within the company. Problems in formability are addressed and reflected in the next molds that will be produced. |

|

|

|

|

|

|

|

|

|

Design and Making of Plastic Injection Molds

GIFU SEIMITSU SEISAKUSHO CO., LTD.

3-129, Tokuda, Ginan-cho, Hashima-gun, Gifu Prefecture 501-6016

Phone: 058-271-2228@MAIL:gimitu@gimitu.co.jp |

|

|

|

|

|